- Electronic Transmitters

- Low Pressure Transmitter

- Pneumatic Transmitters

- Pressure Transmitters

- Temperature Transmitters

- Level Transmitters

- Wireless Transmitters

- Multivariable Transmitters

- Gauge Pressure Transmitters

- Flow Transmitters

- Inline Pressure Transmitter

- Coplanar Transmitters

- Differential Pressure Transmitters

- Absolute Pressure Transmitters

- Continuous Level Measurement

- Transducer

- Control Valves

- Controllers / Positioners

- Gauges

- Sensors

- Thermocouples and Thermocouple Assemblies

- Level switches

- RTDs-Resistance Temperature Detectors

- Instrument Manifold

- Accessories

- Wire Products

- Wireless Products

- Detectors

- Miscellaneous products

- Alarms and signaling devices

- Gas Detectors

- Gas Monitoring Systems

- Flame Detectors

- Hart communication tool

- Hydrostatic level probes

- Displays / Digital indicators

- Diaphragm seals

- Thermowells

- Thermometers

- Power supplies, Isolators, Signal converter

- Automotive Equipment

- Signal generators

- Data-loggers, Recorders

- Humidity and Temperature Transducer

QUICK ENQUIRY

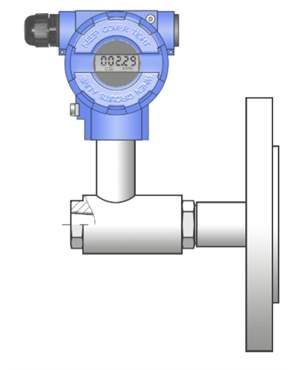

Differential Pressure Transmitters

Differential pressure measurement is an important requirement across industries. Differential pressure is the difference between any two measured pressures, and this measurement is performed using differential pressure transmitters. These transmitters always make a comparison between the low side and high side pressures. They convert these pressure measurements into a 1-5Vdc output or 4-20 mA signal. These signals serve as input to a recorder, a controller, or any similar device.

The Transmitter Shop (TTS) offers differential pressure (DP) transmitters from Emerson and other industry-leading brands. Rosemount differential pressure transmitters are used for sensing the level of fluid in condensers to acquire quantitative data of performance in the process, and so on. Over the years, we have helped clients improve their process efficiencies by delivering them new, surplus, and reconditioned DP transmitters at discount prices.

Filter By

Elements of Differential Pressure Transmitter

The pressure transmitter of this type uses two elements for differential pressure measurement. Most differential pressure transmitters, including Rosemount differential pressure transmitters in our selection, feature the following elements, which play a key role in their functioning.

Primary Element and Secondary Element:

Of these, the primary element is known to produce a difference in pressure, so is known as the high side. However, the secondary element is known as the low side, and it measures the pressure difference produced by the primary element. Venturi tubes, orifice plates, pitot tubes, flow nozzles, and laminar flow elements are a few types of primary elements found in differential pressure transmitter. Sensors are the secondary elements found in differential pressure transmitter. Strain gauges and vibrating wires are used as sensors in these pressure transmitters. These sensors transmit an electrical signal, which is sent to the housing.

Protective Electronic Housing:

This electronic housing protects the sensor, and it interprets the signal received from the secondary element into the voltage or current that can be easily read by the control system.

Differential Pressure Transmitters Working Principle

DP transmitters comprise a sensor module, an electronic housing, and process flanges. The sensor module features two sealed fluid systems, a pressure sensor, two isolation diaphragms, and an overpressure diaphragm. The electronic housing features an amplifier board and wiring terminals. The flanges serve as the outer wall of input chambers and they provide necessary LO and HI port connections.

In the sensor module, the electronic pressure sensor is positioned on the micro diaphragm, which creates a barrier between the two fluid systems. Of these two, one system corresponds to the LO pressure input and other to the HI pressure input. The isolation diaphragm is named so because it helps isolate the fluid system from the input pressure. These isolation diaphragms will retract or compress whenever a differential pressure is applied across the LO and HI ports. This retraction or compression usually occurs in response to the pressure applied. There are situations when the pressure applied across LO and HI ports may exceed the highest limits specified. In this condition, an overpressure diaphragm takes the control of the system, and stops overpressure from affecting the sensor.

The movement of isolation diaphragm under differential pressure gives valuable information on the variables in sealed fluid systems, which are being detected by the sensor.

Types of Differential Pressure Transmitters Provided by TTS

At TTS, we help clients choose from the following differential pressure transmitters of Rosemount brand:

-

3051S:

The Rosemount 3051 pressure transmitter has set industry standards for pressure transmitters. These Rosemount DP transmitters will enable you to gain more control over your process. This pressure transmitter is available in differential, gauge, and absolute pressure configurations. 3051S is a differential pressure transmitter, which is widely used in service industries for flow measurement due to the following benefits that they offer:- They are offered as pre-assembled to primary elements that ensure easy installation.

- This pressure transmitter features an all-welded hermetic SST SuperModule™ platform and delivers a 15-year limited warranty and 15-year stability.

- They are leak-tested as well as calibrated to reduce leak points.

- Rosemount 3051 DP transmitters feature local operator interface with easy-to-offer menus, as well as in-built configuration buttons

- They assure 200:1 range down that produces reliable measurements and flexibility.

-

2051:

The Rosemount 2051 transmitter assures reliable differential pressure flow measurements. The following are a few beneficial features of these pressure transmitters:- These pressure transmitters can perform up to 0.05 of span accuracy and assure range down up to 100:1.

- They are ideal for differential pressure measurement up to 2000 psi (137,9 bar).

- The transmitter features a local operator interface that features built-in configuration buttons and easy-to-use menus. The interface enables easy commissioning.

- Rosemount 2051 pressure transmitter features a coplanar platform that enables integration of manifolds, primary elements, and remote seal solutions.

-

1151:

This transmitter from Rosemount is known for its longevity and field-proven reliability. Rosemount 1151 transmitter is available in differential, absolute, and gage pressure measurement configurations with integrated solutions for level, pressure, and flow measurements. This Rosemount differential pressure transmitter has gained immense popularity over the last 35 years owing to its following features:- These DP transmitters offer excellent performance in the harshest work environments.

- Through ongoing efforts for improvement, the reference accuracy of ±0.075 has been achieved.

- The smart electronics in this Rosemount DP transmitter offer the rangeability of 50:1, which helps reduce the number of transmitters to be specified, procured, as well as stored in inventory.

- These DP transmitters are also available in high-pressure models, which can withstand static inline pressures up to 4500 psi.

The Accuracy of Differential Pressure Sensors

The accuracy of differential pressure sensors is crucial in various applications, particularly in industries like automotive, aerospace, HVAC, and manufacturing. These sensors measure the difference in pressure between two points in a system, which can be indicative of various parameters such as flow rate, liquid levels, or gas pressure. Accurate readings are essential for ensuring safety, efficiency, and compliance with industry standards.

The accuracy of a differential pressure sensor depends on several factors, including sensor design, calibration, and environmental conditions. High-quality sensors are often calibrated and characterized to provide precise measurements. Regular maintenance and calibration are necessary to maintain accuracy over time. Environmental factors such as temperature and humidity can also affect sensor performance, so understanding and accounting for these variables is essential. In critical applications, the choice of differential pressure sensor and its proper installation can significantly impact the overall system accuracy, making it imperative to select the right sensor for the specific requirements and conditions.

Troubleshooting Guide of Differential Pressure Transmitters

Although designed for harsh environments, differential pressure transmitters also fail to perform at times. In such cases, troubleshooting helps you identify the cause of malfunctioning and take necessary action. It is always recommended to check the manufacturer’s manual while troubleshooting differential pressure sensors. This would help you easily identify the issues and proffer remedies easily. There are can be different causes of malfunctioning, the following section describes a few common causes and their remedies.

Output:

If the output is low, high, or there is absolutely no output at all then it could be due to dysfunctioning of loop wiring, impulse piping, and sensing element. You can verify these elements in the following way:

-

Loop Wiring:

- Check the voltage being delivered to the transmitter.

- Check for multiple grounds, open circuits, and shorts.

- Verify the loop impedance and check the proper polarity at the terminal.

-

Impulse Piping:

- Check for blockage or leaks in the piping

- Check if there is any liquid or gas entrapped in the piping.

- Check for settlements of debris or sediment on the transmitter.

-

Sensing Element:

- Check for any physical defects on the sensing element.

- Disassemble the sensing element as per the manufacturer’s recommendations.

Calibration:

If you feel that the transmitter is not calibrating properly, you need to check the pressure source, meter, power supply, transmitter electronics, and sensing element.

-

Pressure Source:

- Check for any leaks or restraints on the pressure source.

- Check the pressure setting around gauge or weights.

- Ensure the pressure source is accurate.

-

Power Supply and Meter:

- Check the output voltage at the transmitter.

- Ensure the meter is working fine.

-

Transmitter Electronics:

- Check for the cleanliness of the connectors.

- Verify if the connectors are working fine.

You can check the sensing element in the same way as described above. Remember that sensing element cannot be changed on field, and you can approach the manufacturer or the field expert for the replacement.

Applications of Differential Pressure Transducer

Differential pressure transmitters are used for measuring the following:

-

Density:

When used for measuring density, these transmitters measure the pressure difference between two points of the vertical plane. This difference in pressure helps get the exact density value. The density is always proportional to the pressure difference. -

Flow:

Differential pressure transmitters are used for flow measurement across venturi tubes, orifice plates, pitot tubes, as well as other flow applications. Differential pressure sensors for flow measurement take advantage of the square law relationship that exists between the flowrate and differential pressure. So, when buying DP transmitters for flow measurement, always consider the following factors:- Type of fluid

- Temperature

- Line pressure

- Flow turndown

-

Level:

In many industries, DP transmitters are used for level measurement. These devices are used in sealed tanks. They compare the pressure at the top and bottom of the tank. The shape of the tank is one of the important considerations to be made when buying these devices for level measurement. Although most transmitters can compensate for regular shaped and standard tanks, they may not be ideal for irregular shaped tanks. Hence, check on this fact, if you are considering irregularly shaped tanks. -

Viscosity:

When used for viscosity measurement, the differential pressure transmitter takes into account the differential pressure on the orifice plate. During the process, a fluid is pumped through an orifice plate at a fixed rate using a pump that works on a positive displacement principle at a specific pressure and temperature.

Industrial Uses of Differential Pressure Transmitters

We have been delivering Rosemount differential pressure transmitters to our clients across industries such as:

- Water Treatment

- HVAC

- Food and Pharmaceuticals

- Paper

- Chemical and Petrochemical

- Offshore and Nuclear

- Subsea

Benefits of Using Differential Pressure Sensors

Today, it is easy to find pressure transmitters designed for measuring density, flow, level, and viscosity. However, differential pressure transducers are widely preferred over other types of transducers for differential pressure measurement due to the following reasons:

- Differential pressure sensors possess a flexible design, which enables their easy mounting in any application.

- All Rosemount differential pressure transducers provided by us assure high accuracy and they are provided with a local operator interface.

- These pressure transmitters are proven to work best in the harshest environments, which makes them an ideal choice for applications, where other pressure transmitters fail to perform.

- They are leak-proof and tested for reverse wiring and other malfunctions.

We understand the importance of delivering quality pressure transmitters and accessories. This is why we only stock products from industry-leading brands. Differential pressure transmitters play a key role in the process results, and we cannot disappoint our customers who approach us with key parameters such as safety and productivity in mind. Owing to such a vast selection of differential pressure transmitters on sale, it is quite obvious to get confused. To ease the selection, you can get in touch with our team of experts today. Having spent more than three decades in the industry, they perfectly understand your needs and requirements. For more information on any of these differential pressure transmitters or other transmitters, please contact our team today.

.webp)

.jpg)