- Transducer

- Transmitters

- Control Valves

- Controllers / Positioners

- Gauges

- Sensors

- Thermocouples and Thermocouple Assemblies

- Level switches

- RTDs-Resistance Temperature Detectors

- Instrument Manifold

- Accessories

- Wire Products

- Wireless Products

- Detectors

- Miscellaneous products

- Alarms and signaling devices

- Gas Detectors

- Gas Monitoring Systems

- Flame Detectors

- Hart communication tool

- Hydrostatic level probes

- Displays / Digital indicators

- Thermowells

- Thermometers

- Power supplies, Isolators, Signal converter

- Automotive Equipment

- Signal generators

- Data-loggers, Recorders

- Humidity and Temperature Transducer

QUICK ENQUIRY

Diaphragm seals

A diaphragm seal, is a type of pressure seal, which is used in pressure measurement systems to shield the pressure transmitter from harsh or harmful environments. It works as a safety shield for the sensor. At The Transmitter Shop (TTS), we offer top-quality diaphragm seals that will protect your pressure transmitter from any harmful industrial environments. Our pressure seals are tailored to meet the needs of industries like oil and gas, chemical processing and food manufacturing. Contact our team now to know more!

Filter By

How Do Diaphragm Seals Work?

Diaphragm seals act as protective barriers that prevent harsh substances from reaching the sensitive components of pressure measurement devices. Here's how they work:

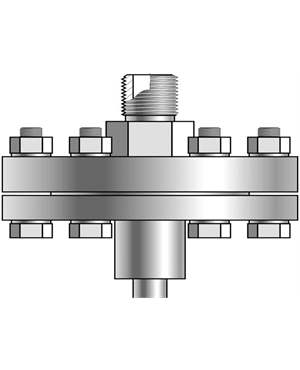

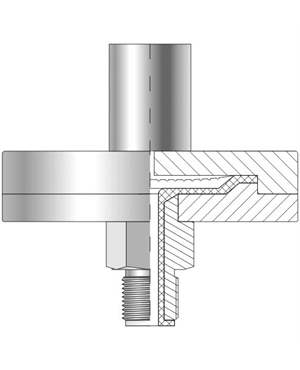

A diaphragm seal consists of a flexible diaphragm, usually made from stainless steel or elastomers, clamped between two flanges. One side of the diaphragm faces the process media (liquid, gas, or slurry), while the other side is connected to a pressure gauge or transmitter.

When the process media exerts pressure, it causes the diaphragm to flex or move. This movement is transferred through a filled liquid to the pressure-sensing device. As the diaphragm moves, it deflects and the amount of deflection is measured and converted into a pressure reading.

In more advanced setups, the deflection of the diaphragm can change the electrical resistance within a strain gauge, allowing for precise digital pressure readings. The diaphragm seal ensures accurate pressure measurements even in extreme conditions, protecting the sensor from damage, corrosion and contamination while maintaining the system's integrity.

By isolating the sensitive instruments from direct contact with the process fluid, our pressure seals help extend the lifespan of pressure measurement equipment, making them indispensable in industries dealing with hazardous, corrosive, or high-temperature environments.

Types of Diaphragm Seals Available at The Transmitter Shop

At The Transmitter Shop, we offer various types of diaphragms, each designed to meet the specific needs of different industries:

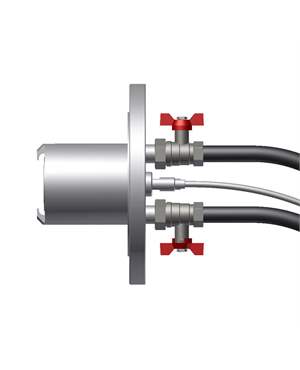

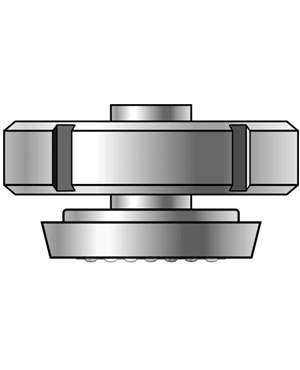

- Flanged diaphragm seals: Flanged diaphragm have a flange connection that allows for easy integration into existing systems. They are ideal for applications where protection from harsh chemicals, high pressure, or extreme temperatures is required. Under this category, we offer (S-P), (S-T), (S-TK-P) and (S-Ch) seals.

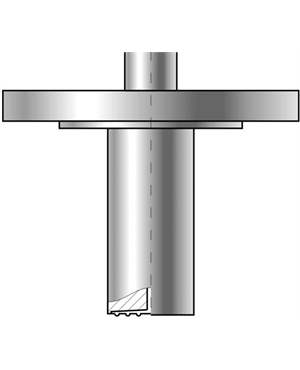

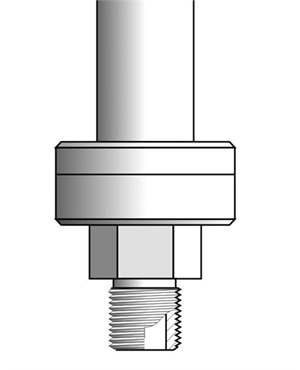

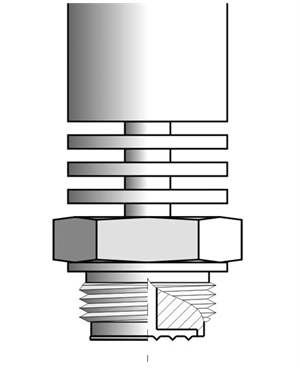

- Threaded Diaphragm Seals: Threaded seals have a compact design and can be fitted in small areas. They are available in S-Comp, S-Comp 10MPa, S-CompCh, S-Mazut and S-RC models. These seals are required where a threaded connection is needed, providing strong, secure sealing for systems under pressure.

- Sanitary Diaphragm Seals: These seals feature hygienic process connections that will ensure efficient cleaning. Also, they help to prevent contamination during hygienic production processes. These are required in the food and beverage industry where contamination must be avoided at all costs.

No matter the application, diaphragm pressure seals from The Transmitter Shop ensure reliable, accurate and protected pressure measurement systems, tailored to your unique needs.

Applications of Diaphragm Seals

Our seals are used across industrial applications where accurate pressure measurement is required and equipment protection is essential. Here are some key applications:

- Chemical processing: Industries dealing with corrosive, hazardous, or aggressive chemicals need diaphragm seals for essential pressure measurement protection. This is done by isolating pressure transmitters and gauges from direct contact with dangerous substances. The pressure diaphragm seal ensures that the sensor remains safe and operational, even in highly corrosive environments.

- Oil and gas industry: The oil and gas industry operates under extreme conditions. Our diaphragm mechanical seals are used to protect pressure sensors from the harsh elements found in drilling operations, refineries and offshore platforms. The diaphragm mechanical seal protects sensitive equipment while delivering accurate pressure readings in challenging conditions.

- Pharmaceutical manufacturing: Maintaining precise pressure measurements is crucial in pharmaceutical production. Pressure seals made from materials resistant to contamination help safeguard the quality of products and maintain the functionality.

- Power generation: In power plants, our pressure diaphragm seals are used to protect pressure sensors from the extreme heat, steam and other high-pressure environments found in boilers, turbines and reactors. This ensures that power plants operate efficiently and safely.

- Water treatment and waste management: In water treatment facilities, diaphragm seals prevent pressure transmitters from coming into contact with corrosive substances found in the water supply. Whether dealing with chemicals or dirty water, our seals ensure that pressure measurement remains accurate and protected.

Materials and Customization Options

At The Transmitter Shop (TTS), we understand that every industrial application has different requirements. Thus, we offer a wide range of materials and customization options for our diaphragm seals:

- Range of materials available: The material selection for diaphragm seals directly impacts the seal’s ability to resist corrosion, withstand high temperatures and maintain durability under pressure. We offer various materials, allowing you to choose the best option for your process conditions. These include stainless steel, Zirconium, Hastelloy and Monel.

- Custom seals design: In addition to our standard diaphragm seals, we offer custom seal designs to meet the specific needs of your process. Custom designs can accommodate specialized applications, including the size and shape of the diaphragm, flange connections, or special sealing materials.

- Fill fluid options: The fill fluid inside the diaphragm seal plays a crucial role in transferring pressure from the diaphragm to the pressure transmitter. Our fill fluid options include glycerin, silicone oil, mineral oil and specialized fluids.

Advantages of Using TTS Diaphragm Seals

Here’s why you should choose our pressure measurement protection seals for your application:

- Enhanced pressure management protection: Our pressure seals serve as a protective barrier between the pressure transmitter and the harsh process conditions, ensuring that your sensitive equipment remains intact.

- Reliable performance in harsh environments: Our diaphragm mechanical seals are designed to withstand the most demanding environments. Whether you are working with high-pressure systems, aggressive chemicals, or high temperatures, these seals are built to endure.

- Easy integration and maintenance: Our diaphragm mechanical seals are designed for easy installation and integration into existing systems, minimizing downtime and ensuring smooth operations.

- Cost-effective solution: By extending the life of your pressure transmitters and reducing the risk of damage due to harsh conditions, our diaphragms can ultimately lower maintenance and replacement costs.

- Versatility across industries: Our diverse range of materials and seal types ensures versatility across industries. We provide solutions tailored to meet the specific demands of nearly any application.

The Transmitter Shop offers a reliable range of diaphragm seals engineered for accuracy, durability and long-term performance. Whether you are dealing with corrosive media, high-pressure or hygiene-critical processes, we have the right solution tailored to your industry.

Contact our sales team today for expert guidance and discover the ideal diaphragm seal to protect your equipment and ensure precision under pressure.

Frequently Asked Questions (FAQ):

1. What fill fluids are used in diaphragm seals?

Common fill fluids include:

- Silicone oil (standard)

- Glycerin-water (for sanitary use)

- Halocarbon oil (for oxygen service)

- Inert fluids (for high-temperature or special applications)

The choice of fill fluid affects performance, especially in extreme temperature environments.

2. Can diaphragm seals affect measurement accuracy?

Yes. Improper selection, incorrect fill volume, long capillaries, or air bubbles in the system can impact accuracy.

3. How do I select the right diaphragm seal for my application?

Consider the following factors:

- Process temperature and pressure

- Chemical compatibility

- Required accuracy and response time

- Connection type (flanged, threaded, sanitary, etc.)

- Mounting location and distance from transmitter

4. What materials are diaphragm seals made from?

Diaphragm seals are available in a wide range of materials based on process compatibility, including 316L Stainless Steel, Hastelloy C, Monel, Tantalum, Zirconium, PTFE / Teflon-lined.

Choosing the right material depends on the chemical compatibility, temperature, and pressure of the process fluid.

.webp)